Piezoelectric materials are capable of transforming mechanical strain and vibration energy into electrical energy. It does not store any personal data.The piezoelectric effect is extensively encountered in nature and many synthetic materials. The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. The cookie is used to store the user consent for the cookies in the category "Performance". This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. The cookies is used to store the user consent for the cookies in the category "Necessary". The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". The cookie is used to store the user consent for the cookies in the category "Analytics". These cookies ensure basic functionalities and security features of the website, anonymously. Necessary cookies are absolutely essential for the website to function properly.

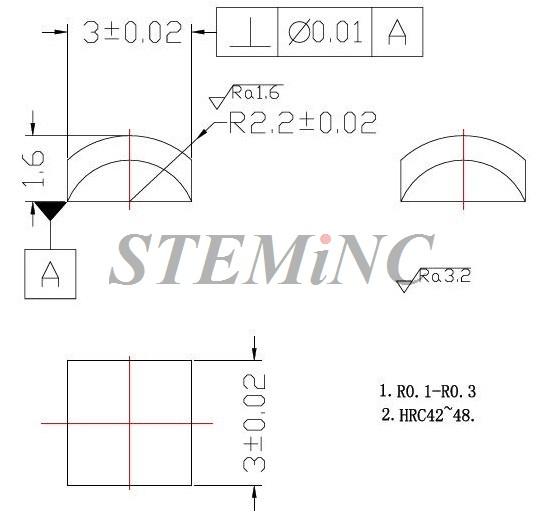

Please contact us with your piezo element requirements to see how Piezo Direct can support your project! All standard piezo elements are available for customization to meet your specific needs. The applications of piezo elements is virtually limitless, and Piezo Direct is dedicated to continuing the exploration of piezoelectric capabilities by delivering top of the line standard piezo element products. The fine movement generation afforded by piezo elements is increasingly harnessed everyday, from high precision motion technologies to household commodities. Medical and commercial applications that require precise release of a solution often rely on atomizer piezo elements. Piezoelectric atomizers are used for atomizing liquids and fluids. These piezo strips bend to create displacement or generate electricity. Piezoelectric strips are thin piezo elements made of one or two layers of active piezo material. Piezo discs are extremely small, thin, and lightweight piezo elements, making them very suitable as actuator, sensor, or transducer piezo elements. The most displacement occurs at the center of the disc piezo element, forming a dome or bowl.

Piezo disc piezo elements deform when a voltage is applied. Multilayer stack piezo elements come in a variety of shapes and sizes, including rectangular, ring, and circular stacks. Stack piezo elements are manufactured by combining the expansion power of many individual piezo elements to amplify the power. Multilayer piezo stack actuators are commonly used for delivering high force generation and precise displacement.

#Piezo actuator and sensor full#

All piezo elements, standard and custom, are made to order.Įxplore the full capabilities of Piezo Direct standard piezo elements below. However, the piezo elements below have some standard specifications listed, meaning the tooling has already been developed for that spec. Please note that standard products are not available off the shelf – everything from Piezo Direct is custom made. Our standard piezo elements are designed with several standard specifications, available as is or with any customizations needed to meet your requirements. Piezo Direct offers a wide range of piezo elements, from standard products to fully custom products. Piezo Direct’s piezo atomizers, multilayer stack actuators, piezoceramic disc actuators, and piezo bending actuators are widely utilized in many applications across a diverse range of industries. Our dedicated team of engineers is also available for testing and design assistance to build the ideal piezo element based on your requirements.

Our standard piezo elements range from multilayer stack actuators to piezo atomizers and ultrasonic nebulizers. Piezo Direct manufactures a wide range of piezoelectric products, ready to ship around the globe.

0 kommentar(er)

0 kommentar(er)